WAGO-I/O-SYSTEM的新型PROFINET適配器帶有內(nèi)置交換機,用戶在應用開放式自動化工業(yè)以太網(wǎng)標準時就會更加容易。可通過內(nèi)置交換機進行線形布線或外置交換機進行星型布線,并且具有自動協(xié)商、自動交叉和全雙工的性能。利用PROFINET,可以在工業(yè)以太網(wǎng)上將現(xiàn)場設備靈活和完美集成。

WAGO-I/O-SYSTEM new PROFINET coupler with built-in switch, the user in the application of an open Ethernet standard automation industry will be much easier. Topology line through the built-in switch or topology star through external switch, and this coupler has performance of auto-negotiation, auto-cross and full-duplex. Using PROFINET, Industrial Ethernet can be flexible and will be the perfect integration of field devices.

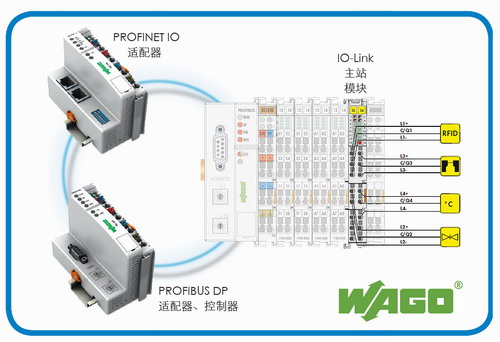

隨著日益復雜的產(chǎn)品、生產(chǎn)的靈活化以及對于質(zhì)量保障的高要求,均需要采用智能化、可設置參數(shù)的傳感器。其中用于連接控制系統(tǒng)和加工系統(tǒng)的必需的多種不同接口,現(xiàn)在都通過IO-Link實現(xiàn)了標準化。可通過3線接點將過程數(shù)據(jù)以及非循環(huán)數(shù)據(jù)傳遞給相應設備(傳感器和執(zhí)行器)。主站模塊和設備的描述文件對其功能和性能參數(shù)進行了詳細說明,還可通過WAGO-IO-Check軟件對參數(shù)進行調(diào)整。出于需要更換設備后,所有配置參數(shù)都可自動重新生成,無需維護人員再次設置。因此,規(guī)劃、安裝和運行均得到了明顯簡化!

Increasingly complex products, manufacturing flexibility and high demands on quality assurance require intelligent, configurable and programmable sensors. IO-Link now elegantly standardizes the required, varying interfaces for connecting to a control system and tooling. A 3-wire connection can communicate process data, as well as acyclic data to both sensors and actuators. The functions and performance data are defined in device description files for master and devices; these are easy to customize via WAGO-I/O-CHECK. If a device has to be replaced, the configuration and parameterization can be automatically restored without the intervention of maintenance personnel. Project design, installation and operation are thus simplified significantly.